|

Total Compliance Solutions for the Future

Part 1 of a TÜV Product Service Portfolio for Compliance

Increasingly manufacturers of products of all kinds are compelled to provide assurances to their marketplace that their products are safe and fit for their intended purpose. They are also faced with increasing competition from around the world as well as internal pressures to cut costs and reduce the product time to more markets!

The most familiar legislation to European manufacturers is embodied in the European Union Directives which lead to CE marking of products, but virtually every marketplace in the world has its own regulations for accepting products onto that particular market.

In addition to the legislative requirements there are also commercial /contractual requirements – many organisations have their own standards and procurement requirements to which suppliers must adhere. Furthermore, manufacturers themselves very often set their own standards of quality and performance simply to ensure that their products surpass customer expectations.

Manufacturers can demonstrate compliance in a number of ways. This will typically involve some degree of type testing, backed up with consultancy and possibly third party certification. Sometimes they carry out an assessment themselves, but the equipment and/or expertise required is beyond the scope of most companies. In any case, there is perceived added value in testing by an independent third party.

Product Certification is also perceived as adding value and aiding market access, particularly where retailers are concerned, and generally requires assessment by an accredited body to demonstrate compliance with specified requirements. TÜV Product Service/BABT is one of several organisations in the UK which specialise in product assessment and certification.

What do you mean by Compliance? So what exactly do we mean by compliance? What does it involve? Compliance involves one or more of the following key services:

· Consultancy

· Testing

· Certification

Consultancy – Ensuring cost-effective and timely compliance One of the goals of a product manufacturer is to gain market access quickly and cost effectively. To achieve this for new technologies and new markets means drawing on an incredible amount of knowledge, not always available on tap internally.

The benefits of taking on board technical consultants are many fold, not least that the manufacturer doesn’t have to employ full time experts covering all the technological and compliance requirements for all possible products and markets. Consultancy used during the development process provides manufacturers with the optimum route to achieving compliance and market access. Specific resource depending on the project can be drawn upon, supplementing the manufacturers existing in-house resource.

It doesn’t stop there though, by employing a consultant, manufacturers can also benefit from the experience of dealing with experts and hence use the experience to develop their own skillset, thereby developing their own processes and knowledge base.

Examples of technical consultancy are many fold and range from upfront product design, design tips, advice on the technical requirements of the target market so these can be built into the product, product review, import restrictions, etc… Essentially, any aspect of the product life cycle – both commercial and technical – can be outsourced, providing the manufacturer with the opportunity to focus on their own core competencies, invariably design, build & sales/marketing.

Testing – demonstrating compliance As mentioned earlier, testing in one form or another against recognised standards, provides important information and data regarding a products performance. TÜV Product Service/BABT can apply a number of tests to ensure that a product is fit for market.

· Safety assessment proves that the product won’t harm the user.

· Network Performance/Interoperability testing ensures that it will function within its intended operating environment, for example the public telephone network.

· EMC testing of electrical/electronic products is performed to ensure that the likelihood of interference is minimised.

· Environmental testing ensures that a product will function and survive in its intended physical environment

· RF testing proves that it won’t cause harm to the user and does not pollute the radio frequency spectrum.

Better that a product fails these tests in a lab than in the field. The good will of customers is a valuable business asset, not to be lightly dismissed.

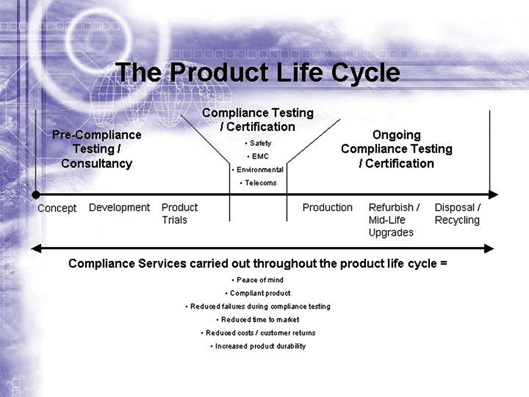

It is worth mentioning here the importance of testing throughout the product life cycle, both before and after the formal compliance testing.

There is an example of a company that undertook HALT, (highly accelerated life test), during development of a product and this revealed a fault mechanism which cost USD80 to fix. The company estimated that if the fault had occurred on its customer’s premises, it would have cost USD560 000 to fix! TÜV Product Service/BABT works in partnership with manufacturers to devise an assessment strategy that will be effective throughout product development, saving time and money by delivering a right-first-time product and minimising time to market.

Certification – Adding value to compliance Certification is a key tool used to gain greater market acceptance and to minimise the risk of non-compliance.

In many cases the application of regulatory marks such as CE marking may not necessarily mean the product has been tested against relevant technical requirements, whereas an independent certification mark is a clear guide that testing has been carried out by an independent third party. Furthermore an independent certification mark is seen as a differentiator in an increasingly competitive world. A further benefit of product certification is the ongoing audit of the production facilities or regular product checks.

Product certification is an official statement of conformity to a standard or regulations, accompanied by appropriate documentation, as specified by market or customer requirements.

Certification can considerably assist a product’s acceptance into a market, particularly where a brand is unknown or new technology is involved. It can often be consumer driven, sometimes to the extent that the TÜV mark (see example in diagram), is very influential for products entering key markets around the world. Certification marks also demonstrate the manufacturer’s commitment to product quality to importers, retailers and consumers and is seen by many leading organisations as a passport to trade in markets worldwide.

Today, it is a popular strategy to undertake the requirements of regulatory compliance and certification in tandem, providing the most cost-effective route to achieving market aims through a combination of access and consumer appeal. Indeed, as a major certifier of quality & environmental management systems and provider of regulatory compliance and certification services, TÜV Product Service/BABT provides a one-stop shop for certification. The manufacturer benefits from simplified lines of communication and considerably reduced costs. Systems of combination marking such as the TÜV-Mark and BABT Octagon Mark send out a powerful message to potential customers of a product’s quality.

The delivery of these certification services within close partnerships enables TÜV Product Service/BABT to provide manufacturers with up-to-date information on changes regarding technical regulations, and on developments in achieving approval and market access.

The importance of accreditation So a compliance partner has been identified. How do you know they will perform, who assesses the assessors?

While customer dissatisfaction can be damaging enough to a business, there are potentially far more devastating consequences of product failure in the field. Bad publicity can put a company out of business overnight; litigation over injury or death caused by faulty products can prove ruinously costly or result in imprisonment. Manufacturers place great faith in the compliance provider of their choice to protect them from this kind of catastrophe. How can they be certain that their trust is not misplaced?

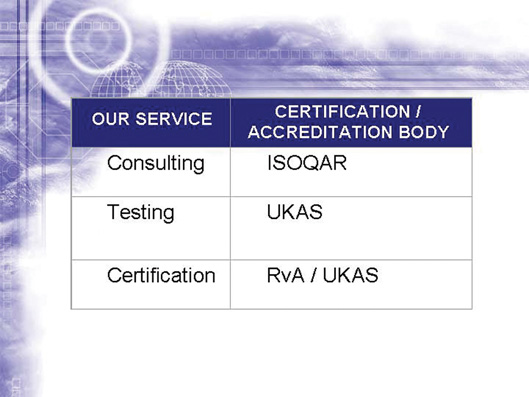

Accreditation is a process by which an organisation recognised by government assesses, against internationally agreed standards, organisations that provide certification, testing, inspection and calibration services. Accreditation demonstrates the competence, impartiality and performance capability of these evaluators. One of the best known accreditations is awarded by UKAS (United Kingdom Accreditation Service), and shows that a test laboratory/certification body has been independently assessed and possesses an acceptable level of equipment and expertise.

Checking out the accreditations can save manufacturers from making costly mistakes in their choice of a compliance partner. Furthermore, in the event that a manufacturer becomes involved in litigation, the involvement of a competent third party can assist substantially in reducing liability through showing due diligence.

TÜV Product Service realises the benefits of independent checking of the processes we employ, below is a chart of the Accreditation/Certification bodies that assess our processes.

Trends in achieving market access There is an increasing change within compliance service providers to move towards the provision of these services throughout the product life cycle, as well as an increasing move towards provision of knowledge and problem solving solutions.

One example is that of manufacturers requesting new approaches to safety compliance, reflecting changing requirements for fast, flexible compliance services. Ken Webb, Technical Consulting Manager at TUV Product Service states “The Safety Compliance Assessment provides a cost-effective alternative to formal product safety testing. It has proved to be an outstanding success with electrical product manufacturers, who particularly value this innovation as a speedy and effective route to CE marking their products. The service offers them the confidence that their products comply with the safety requirements of the EU Low Voltage or Machinery Directive and, if applicable, the Radio & Telecommunications Terminal Equipment Directive, backed by the name of one of the world’s leading testing and certification bodies.”

Mr Webb continues “An important advantage of the Safety Compliance Assessment is that it invariably takes just one day. The service can be used for many products that are intended to be placed on the market within the EU and are subject to CE marking. The ensuing report can be used to demonstrate compliance with the relevant Directives and is also ideal for identifying major problems at the design stage.“

Findings are detailed in a test report delivered by e-mail, including a summary statement detailing if the product construction meets the essential requirements of the Directives, observations, comments & non-compliances, and recommendation of any tests that are required to supplement the review.

Because the assessment can be carried out at the manufacturer’s premises, it saves time and gives the manufacturer the benefits of a dedicated engineer on site who can be used for training staff, review and repair on site in the event of a product failure, and the continued presence of the test engineer to perform a re-assessment when fixed. The testing can result in a CB report, NRTL certification, GS or TÜV Octagon marking, providing manufacturers with access to a wide range of countries worldwide.

The future for TÜV Product Service The Safety Compliance Assessment is just one innovation at TÜV Product Service/BABT geared to better meeting the needs of manufacturers and diversifying client groups such as importers, governments, and so on.

Chris Baird, Marketing Manager at TUV Product Service/BABT states “Today, Market Access Services more accurately describes a total solution which delivers focused information, testing, consultancy and certification services. We are always looking at ways of finding more cost effective and timely solutions for clients and fully understand the issues faced – short timescales, first to market and the need to innovate whilst reducing costs. The future is likely to see more customer focussed and flexible services, including:

· a technical help desk whereby manufacturers can book blocks of consultancy time at the start of the year and call it off on an ad hoc basis whether that be to attend and offer advice during a project initiation / design review meeting or managing a products approval process

· product lifecycle services whereby TUV Product Service/BABT gets involved throughout the lifecycle offering technical and regulatory advice at project concept through development testing to compliance testing, field trials, marking and certification to aid in marketing and training

· market access consultancy whereby TUV Product Service/BABT work with the manufacturer to offer strategic advice on which countries should be targeted and when; available conformity assessment routes and recommendations as well as full approvals management

All of these services will augment an extensive portfolio of marketing support services as well as our provision of the full range of technical and compliance solutions to assist in market access.”

For further information contact TÜV Product Service Limited, Segensworth Road, Titchfield, Fareham, Hampshire PO15 5RH. Tel: (01329) 443322. Fax: (01329) 443421. Email: info@tuvps.co.uk URL: http://www.tuvps.co.uk/

|