|

A Commercial Case for Compliance "The Extra Mile"

By Alan S Payne, EMC and Environmental Consultant

In Product meetings hackles rise at the mention of compliance. The rough cost is calculated and you are sometimes asked if the money would be better spent on marketing.

“Compliance engineering” so often considered a tax on commercial-creativity is potentially much more than a route to legality but for EMC and Safety at least it is often thought to be just that.

The military, aerospace and carmakers have always used “compliance engineering” to increase the tangible reliability and toughness of products. Today this competence is available to all markets and compliance engineers are accustomed to budget restraints within the commercial sector. We must teach industry how to gain real advantages from compliance engineering, not just pay money for the certificate.

Compliance engineers have a better overview of product stability and toughness to that of most purely functional design engineers on account of having seen more product types and use conditions. They will frequently identify and eliminate the causes of malfunctions such as signal degradation and thermal instability.

To the compliance engineer many design errors are so commonplace he can spot them as easily as your GP spots chickenpox, nonetheless these errors can mystify product engineers who are usually too close to the product to see the whole picture.

There are enough real-life illustrations to fill this Journal into next year but I will show two examples that prove firstly ignoring product compliance is a way to lose business and secondly designing for compliance so to improve product function is a way to push competition aside.

In both the following examples the products were “unfit for purpose”. It is possible for a product to pass all of the tests deemed necessary for a legal and recognized level of compliance yet still be “unfit for purpose” this can result from poor investigation of the product working environment or from not taking account of the users expectations. Remember, compliance with a standard does not confer immunity from the law so make sure your product is “fit for purpose” there is no other reason for compliance so make sure you get the advantage and “stick one” on the competition.

In the 70s before EMC entered the collective awareness, a respected maker offered a chart recorder for laboratory use. The recorder had fantastic advertised capability, looked great and had a price tag to match. The recorder was set in a constant temperature room and used to log temperature and humidity. Sadly, it would only do this reliably at night when the estate switched off. In consequence the machine itself was switched off whereupon the print head dried up in two weeks. The maker was contacted only 4 weeks later for a replacement printer head that was unavailable because the product had already been scrapped. The product claimed to meet the legal requirements of the time but the maker had failed to go the “extra mile” to make it “fit for purpose”. Not only had he wasted money on minimum mandatory compliance, he had blown the entire development. Compared to the cost of scrapping his product the cost of adequate compliance must now seem insignificant. Today you must bring a product to market before the competition, no time for fixes.

A maker of a type of laboratory equipment lost business to a competitor on account of contamination of its most important signal output by an internal switch-mode power supply emission. The sad thing is that this maker spent out on EMC and had done a reasonable job with the power supply. He jeopardized the equipment as a result of a late design modification that routed signal cables around the supply so that the near field EMI coupled directly into these.

“Just throw in a couple of capacitors and it will pass EMC” How often have I heard this type of remark? Thoughtless application besides not properly addressing EMC can harm equipment functionality. To my mind it is vital that compliance design not only make legal product but makes product that is better in function into the bargain otherwise compliance will be forever unpopular. Fortunately, properly applied compliance design features do often and tangibly enhance product performance. A little extra effort can bring great advantages. For premium products the customer will expect it.

Careful thought about the way a product performs or is used in connection with compliance aspects can make its use more pleasing or less awkward. This ergonomic facet of good compliance engineering is common to Safety, EMC and Environmental disciplines. Today product designers attempt to make one product useful to many people irrespective of ability, age or infirmity so compliance aspects can only become more important.

In all equipment designs we seek to increase functionality and reduce unwanted consequences of equipment use. In electronic product design we seek to constrain wanted intelligence in “safe” transmission paths, it follows that correct signal balancing, screening and impedance matching enhance signal transfer, reduce distortion and unwanted noise pickup. It is perhaps not so clear that these features usually help legal compliance. It is usually the EMC engineer who points out that the equipment is unlikely to pass testing unless such measures are taken. If the product engineer takes this advice behold his signal to noise ratio improves. It is ever a surprise to me how often standard interface methods are ignored. Most signal intelligence these days carries large amounts of information so it is imperative to protect this precious intelligence from “box to box” and prevent its escape into other channels.

If you consider all compliance design as a barrier separating the wanted from the unwanted you see the connection between functionality and compliance. Some consider EMC and Environment as of little consequence. Safety needs no explanation here. Bad EMC and Environment design is tantamount to designing equipment with bare copper wire for use in water, it might work but for how long?

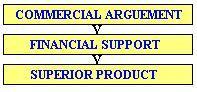

The message is this, unless you justify compliance in terms of increased profit, reduced losses or larger market your boss will take a worse view that he ought. Here are the top arguments in favour:

· Increased market to EU and beyond. · Smaller stock of replacement parts · Less guarantee-period call-outs · Fewer DOA products and sudden violent failures. · Improved brand reputation · Improved functional stability · Less down time “in the field” · Fewer untraceable faults · Peace of mind · No awkward questions

The above may seem obvious, however such arguments will not be foremost in your mind when the boss calls, likely as not under pressure you will resort to negative justifications.

Threats of fines and jail are not very effective even though the possibility of prosecution increases yearly. We do not respond to threats and regard fines as small minded and punitive. Better that we design our products knowing that the compliance engineering has increased the product value then we will do our duty without pain. It is ever a mystery that in the UK we threaten to penalize for the smallest non-compliance rather than give incentives to comply. The psychology is of course wrong.

If you’ve a mind to giving negative arguments to support compliance, particularly if you are considering safety the best negative argument is dressed in positive clothes and runs;

Suppose that we spend no money on safety compliance and this product is huge commercial success sold to thousands of people. What happens if it kills or injures someone? You could always argue, possibly even prove that the user has neglected some safety advice or been downright stupid, so you may pay a fine and that’s the end of it right? Wrong. One article even in a local newspaper can destroy your reputation overnight. The more successful a product is the greater the risk someone will have an unpleasant experience.

Payne’s rule;

If ever you say, “No one could possibly be stupid enough to X” they probably will.

Suggested Reading: “Well deal with a crisis” Page 30 Pipeline magazine Feb 2002.

After 25 years in industry crossing Aerospace, Commercial Electronics and Telecommunications it is my opinion that the skills of compliance engineers are under-used from the commercial standpoint, many product engineers have lost the purpose of compliance and seek mostly legality. Important though this is it is important also to “go the extra mile”

Here is a final example of the ways compliance engineers can contribute by giving thought and guidance to help resolve issues.

We hear much about the safety of mobile phone masts. On the one hand parents of children in particular are concerned about mobile masts near to homes and schools. Likely as not these children also have mobile phones. Surprising for the parents at least is the simple fact that if a mobile phone user is near a mast the amount of power the phone needs to transmit is much reduced thereby making the phone safer. The phone-user is in the phone antenna “near field” where coupling to the head will be efficient and in the mast “far field” where coupling to the body is not (At 1.8GHz this is approximately a separation of 3cm).

Good compliance engineering is much better than insurance; insurance will not prevent accidents. Let us go out and start selling.

For information about services offered by A S Payne EMC and Environmental Consultant call: Tel 01959 577398 or Mobile 07931 343002 or Email alan@perfectinformation.freeserve.co.uk to request a Services Card and Pen. Details may also be found at http://www.perfectinformation.freeserve.co.uk.

|