|

Testing Developments towards lower costs and increased efficiency

By John White, Rainford EMC Systems

Many small and medium size companies are now considering electromagnetic compatibility (EMC) testing facilities in their own plant. Here, John White from Rainford EMC looks at the developments towards lower costs and increased efficiency of the latest compact chambers that will make in-house testing possible.

Historically, smaller companies have tended to incorporate risk evaluation rather than costly regular emc performance evaluations at a test house, while medium to larger companies have taken two routes; either using a test house throughout the year when each product reached a critical stage in development, or taken a technical risk assessment regarding the likely failure and only formally testing when each product neared being ready for market.

In other words the majority of companies have not had the ability to ascertain performance by testing in accordance with regulatory European specifications throughout the development phase. Ideally the product would be checked at each and every stage of the development to see if the EMC signatures were compliant. Configuration or component changes, particularly those which provide cost savings could be quickly incorporated without the risk of failure at a late stage in the cycle.

Fully lined anechoic chambers However, things are changing - the latest draft EN 50147-3 specification defines the use of compact fully lined anechoic (FAC) chamber as an efficient test tool for both Emission and Immunity testing. Although this specification is still in draft, many of the larger European commercial companies defining new test facilities are adopting the FAC approach within tender requests.

The basis of this specification considers lining the groundplane (floor area) completely with absorbing materials in addition to the walls and ceiling when Emission testing. The traditional method within the screened room was to try and mimic the reflective groundplane of an open area test site (OATS) and compare results with the chamber. The accuracy and repeatability of the field is enhanced with fully lined options and additionally provides benefits for immunity testing. In addition, the immunity testing in accordance with the specification IEC 1000.4.3 requires 75 per cent of the measured positions to be compliant, but again, companies are specifying up to 100per cent requirements. The full lining of the chamber floor with high performance anechoic materials helps achieve this 75 to 100 per cent requirement.

Therefore it is not just the known and approved methods of test which are required but leading edge higher performance chambers enabling faster more cost efficient testing to be performed. So, how does the Fully lined chamber (FAC) help? Firstly, there needs to be an understanding as to the test methods employed and correlation accuracy.

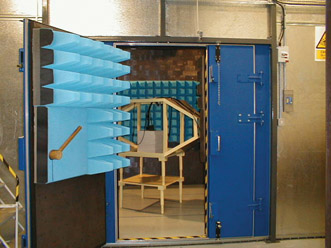

Rainford Compact Chamber with double door

Emission testing in the FAC enables a constant antennae height and does not require the 4m height scan of the groundplane designs previously used, thus considerably reducing the testing time and chamber height.

Immunity testing requires the floor reflection to be absorbed as described earlier, the field uniformity being enhanced by the total lining of the floor. Test correlation techniques are now available to evaluate the performance of the FAC chamber in accordance with an OATS site.

Rainford Compact Chamber with single sliding door

The basis of the design for the FAC is the use of Ferrite tiles which are a nominal 5.5mm thick compared to, say, 1 metre thick traditional foam pyramid linings. This reduces the size of the chamber to about 7m x 3m x 3m and provides very high performance between 30MHz and 1GHz.

As a bonus, ferrite tiles are adequate in compressive strength which, when combined with a rigid chamber floor, enables the permanent fixing of the floor configuration as it is sufficiently load bearing and will easily accept personnel loading and the general EUT traffic of a typical site. The Rainford SmartShield FAC design has enabled even motor vehicles to be placed on a chamber floor without problems. Performance enhancements are available to 40Ghz and above, enabling all requirements to be addressed. For further information contact: John White, Rainford EMC Systems. Tel +44 (0)1942 212071. Fax +44 (0)1942 212051 Email: john.white@rainfordemc.demon.co.uk Web site: www.rainfordemc.com

|