|

Condensation: An Electrical Enclosure’s Nightmare

By Jonathan Brindley, Product Manager for Systems Climate Control Solutions, Rittal Ltd

It’s all about H2O Although many people see humidity as simply the amount of water held in the air, humidity deserves further explanation due to its significance in causing substantial damage to electrical equipment. Consider the internal space of an enclosure as a parcel of air with an amount of energy proportionate to its temperature. Within this parcel, an amount of water (in the form of a gas - ‘water vapour’) is present, and it’s ability to hold the water as a gas depends on its temperature. Basically, the higher the air temperature is the greater the energy level, and the more water vapour that can be held as a gas. This means that if the air parcel were to cool, its energy would decrease and its ability to hold water vapour would reduce.

The following table shows that at 30oC the air can hold water vapour levels of 30 grams m3, when the temperature is lower the energy and its ability to hold water vapour is reduced. It is this relationship between temperature change and water vapour content of the air that concerns the widely used measure of Relative Humidity (RH). RH is a measure of the actual amount of water in the air compared with the amount of water the air can hold at the temperature it is measured. It is displayed as a percentage and illustrated in the last column.

Parcel of Air within Enclosure

At 10oC, the actual water vapour present in the air is equal to the maximum vapour level - Dew point has occurred. Dew point is the moment at which air reaches its maximum potential for carrying water vapour at its current temperature. This is also the point of total saturation, the point at which water vapour condenses from a gas to a liquid. The key factor in preventing the formation of condensation is therefore the amount of energy within the air. At some point the moisture content will stay the same but the temperature may decrease, the balance between air energy levels and moisture content will therefore be out of step, and relative humidity will start its journey towards dew point. Although it is fair to say that condensation will only form at or close to Dew point, it must be noted that oxidation (rusting) can take place at medium levels of relative humidity i.e. 60+% depending on the type and levels of contaminants in the air/water mixture.

Enclosure Best Practice There are instances where users of enclosures are misinterpreting the ingress rating. Choosing the appropriate enclosure to suit the application via the IP rating should however install confidence that the enclosure is fit for its purpose. For example, in environments where high humidity occurs, an enclosure of IP54 or above should be employed to restrict the amount of leakage of warm humid air from outside. Minimising the number of times the doors are opened, and always repairing enclosures that have been damaged, will ensure minimal leakage rates are maintained.

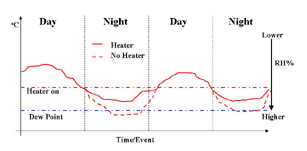

Maintaining minimal leakage rates alone will not prevent condensation forming. To ensure that condensation is prevented, other measures are required which will stabilise the internal air content of the enclosure. One way to achieve this is to install a hygrostat and heater that will sense rising relative humidity levels and provide the air with the required energy. In large enclosures the use of fan-assisted heaters is recommended, and for enclosures located outside, it is good practice to use a standby unit.

IP54 enclosure with doors closed

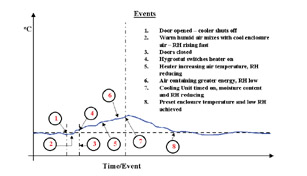

Heating the enclosure air creates higher energy levels and lower RH. By reducing the amount of water vapour in the enclosure air and subsequently the amount of energy needed to keep the water vapour in its present physical state, condensation is prevented. One fortunate side-affect of cooling units such as Rittal TopTherm is that they force water vapour to condense into a liquid during the cooling process. As the air is sucked into the cooling unit, the air is squeezed through the evaporator coil that violently reduces the air temperature to below dew point. The resulting condensation is then transported from the coil to a holding area from which it is propelled, under high pressure, down the condensate drain to the external environment. Using this technique successfully is reliant on low leakage rates, the setting of the internal temperature as high as possible, the employment of door switches and the use of a hygrostat and heater. Where the above requirements are met, actual water vapour will be maintained at a level less than the maximum water vapour. See diagram on next page:

IP54 enclosure

A Dependable Partnership Installing a hygrostat provides the perfect partner for conventional or more modern PTC heaters. A hygrostat is one of the simplest devices used for the control of air stability within enclosures. It is used to turn heaters on and off depending on a preset level of relative humidity. Basic mechanical versions are the most cost effective, are very easy to operate and are based on the use of a man made fibre called polyamide tape. This type of fibre is sensitive to changes in the moisture content of the air, and it is this sensitivity that enables the hygrostat to turn heaters on and off. Rittal PTC heaters have been around for several years though are intrinsically different from conventional heaters in that they contain a resistor. The resistor, which makes up the core of the heater, allows for very efficient conversion of electrical energy into thermal energy. A prerequisite for an optimum conversion of this nature is perfect interaction between the thermal output of the heater, the surface temperature of the heater element and the enclosure air temperature. The surface temperature in a conventional resistance heater is limited via an additional safety thermostat and as a result, the heater is forever cutting in and out, which means that the continuous thermal output actually produced is low. Unlike conventional resistance heaters, in PTCs the power consumption automatically decreases as the intrinsic temperature rises. There are several advantages of this dynamic behaviour including the limitation of its surface temperature thus preventing overheating and fire, its self-regulation of continuous power output, its long service life, and finally its flexibility on low and high voltages.

Just Common Sense Sensitive equipment is always susceptible to problems caused by relative humidity due to natural fluctuations in temperature inside and out of electrical enclosures. By employing Best Practice, relative humidity can be controlled and the formation of condensation on electrical equipment within enclosures can be prevented and oxidation minimised. PTC heaters are a robust, reliable, and cost effective method of controlling relative humidity. Cooling units such as Rittal TopTherm offer a way of reducing the quantity of water in a volume of air, and can work in tandem with a heater to provide an ideal solution for the prevention of condensation. Lastly, in instances where contaminants are known to be present in the air e.g. Sulphur Dioxide, special attention is required since the effects of oxidation is accelerated even at RH levels as low as 60%.

Further information contact John Wilkins, Tel: 01709 704000 e-mail: information@rittal.co.uk

|