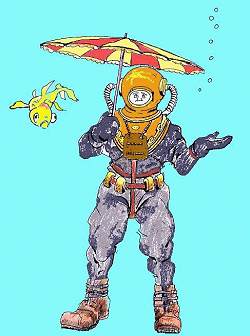

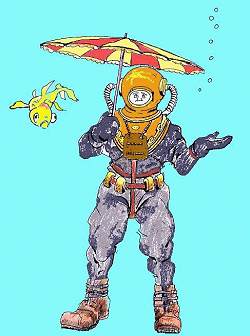

"Two Levels of Protection"

Figure 1.

Product Safety - implications of internal power supplies and energy sourcesBy Gregg Kervill of G.K.Consultants Ltd. |

Please note that the information contained in this series is intended to provide an awareness to product safety and is not intended as an alternative to reading and understanding the relevant safety standard.

Readers with specific requests for future subjects should address them to "The Editor" quoting GKCL05. GKCL05 - Product Safety implications of internal power supplies and energy sources In this article we shall provide details of the common pitfalls made by designers when incorporating mains power sources into their designs - in the following article we will consider each of the classifications under which hazards may arise, simple ways to avoid them and some common mistakes that are made.

To make life simple we will start with the "black" and "white" areas and then work towards the various shades of "grey". This is a useful technique to remember when faced with uncertainty and with no-one to ask: invent an extreme case, consider the essential aspects and then analyse the problem in the context of each point raised.

"Two Levels of Protection" Figure 1. |

The "Operator" may contact the Reinforced Insulation (or equivalent providing two levels of protection - Figure 1) of parts carrying hazardous voltage, energy or current. For example:- the outer covering of a mains power cord, domestic plugs and sockets.

In certain circumstances it may be allowable for the "Operator" to contact Basic Insulation - careful adherence to the standard is essential as is an understanding of the phase "..reasonable use and foreseeable misuse."

The "Operator" may contact conductive parts that are RELIABLY connected to Safety Earth Ground. For example:- the rear surface of a PC power supply, domestic iron or electric cooker. The "Operator" may contact conductive parts that cannot - even under single fault conditions- become hazardous. For example the case of most Personal Computers or a CORRECTLY DESIGNED 19 inch rack system.

If we consider that these are 'basic design rules' there is nothing onerous, difficult or unreasonable about them - and most of us would expect products that we purchase to provide at least this rudimentary level of safety to us, to our employees, and to our families.

If we now take the opposite extreme and consider a badly wired plug that allows the "Operator" to contact the "Brown" (Basic) Insulation of a mains cable. This would cause us all concern - particularly if the "Operator" was our child.

At this point I would like to make a personal comment that I have observed several of these non-compliances in equipment on public display at several National Exhibitions. There are two issues here - one is obviously the violation of Health and Safety legislation but the other point is, perhaps, more important. When we see non-compliant products at exhibitions we naturally consider that the manufacturer does not understand Product Safety and we are therefore reluctant to use - or recommend - their products.

What if there was not even Basic Insulation between the enclosure and the mains supply?

Positive Locking AMP Connector Figure 2.

|

This may come as bit of a shock (no pun intended) but many proprietary rack systems fail to offer a reliable earthing system and quite a few units are supplied with 'push-on pull-off' AMP type connectors which are used for Safety Earth Ground connections: these can easily become detached and Safety Earth Ground lost. The correct type to use are the "Positive Locking" type - Figure 2.

An even more common non-compliance is the "combined" applications of mechanical fixing with Safety Earth Ground using the same hardware. The combined use of mechanical "fixing" with a Safety Earth Ground "connection" is prohibited by most safety standards - this non-compliance is, however, very common.

Look inside most Information Technology equipment and we will find ribbon cable in contact with equipment wiring carrying 230 Volts. Is this acceptable? It is certainly not 'clever' (particularly from the EMC perspective) but it can be compliant with most LVD standards provided that the ribbon cable is rated 300 Volts and provides "Supplementary" Insulation between the SELV signals and hazardous voltage.

Figure 4. |

Fortunately most of the ribbon cable available is rated at 300 Volt so it is becoming more difficult to get this wrong - but we can still see examples of inadequately rated cable in contact with Basic Insulation. The risk is that a single failure in that BASIC INSULATION will apply 230 Volts to the (SELV) conductors within the ribbon cable. - this is because the ribbon cable insulation is not rated for mains voltage and therefore does not exist when 230 Volts is applied to it. Therefore the 'SELV' circuits and all associated outputs become LIVE!

This failure can most usually be seen in badly designed PC Power Supplies where the SELV connection to the cooling fan (BASIC INSULATION) is allowed to contact the exposed tags at the rear of the IEC connectors - Figure 3. When this BASIC Insulation fails then (potentially) all of the PC outputs, mouse, keyboard, modem, printer and the LAN could become LIVE!

Figure 3. |

In the example shown it would be impossible to provide a RELIABLE Safety Earth Ground connection by fitting a Ring-Tag under the fixing nut because:-

For instance:-

EN60204-1 "Safety of machinery - Electrical equipment of machines" §6.2.3 prohibits operator contact with voltages greater than "60 Volts". In contrast to this EN60950 ("Safety of information technology equipment, including electrical business equipment") permits the "operator" to make direct contact with voltages in excess of 20,000 Volts.

At first sight this may appear a contradiction but there is a valid justification for this: we limit the maximum current that can flow through the body so that the risk is defined and controlled.

As an example of this technology:- consider the "touch sensitive" light dimmer. When we touch the metal plate we can feel a slight sensation of roughness. This is due to the small electric current, fed from the mains, that passes through our body.

This is "safe" because the current is so small that it does not harm us and the same is true if the Limited Current Source is supplied from 100 Volts, a thousand Volts, or even a million Volts. Obviously the construction of these Limited Current Sources requires very careful design and manufacturing controls but they are practical and achievable.

This method of protecting the "Operator" from the effects of hazardous voltages can be extremely useful and should not cause us concern (provided that the design and implementation are in compliance with the standard).

Perhaps the only reserve that we might have would be a high energy - high current- and low voltage source as "allowed" by some of the other harmonised standards - SELV at 240 VA is permitted in some countries.

Let us consider another example:-

A mains portable TV set has connections only to Live and Neutral. In order to provide radio frequency coupling for the receiver there is a small capacitor from the receiver to the mains (neutral or live).

Consider a single failure in this component- a short circuit could make all of the Television circuitry (and its aerial) LIVE. Those of us who study the "Recall Notices" in the Sunday papers will have seen a recall describing the same non-compliance.

Figure 5. |

There may be nothing wrong with this but it may require that all of the outputs are treated as "Hazardous Voltages" - this would prohibit their connection to any Information Technology system or any other "Operator" contactable output. It may also require that all wiring and external components be protected by Basic (or even Reinforced) Insulation.

It is important that producers understand their legal duty to supply details of any such limitation or precautions with the product: failure to do so may make them personally liable to criminal prosecution under the LVD and allow 'Enforcement' action to be taken against their products.

© G.K.Consultants Ltd., All rights reserved.

© Nutwood UK Ltd 2001 |

Eddystone Court - De Lank Lane St Breward - BODMIN - PL30 4NQ Tel: +44 (0)1208 851530 - Fax: +44 (0)1208 850871 nutwooduk@nutwood.eu.com |

|

|

|